The continuous analysis and optimisation process has allowed us to achieve high levels of excellence in every production step.

The continuous analysis and optimisation process has allowed us to achieve high levels of excellence in every production step.

Once the customer’s technical details and specifications, such as samples, drafts, 2D or 3D CAD drawings, have been analysed, we proceed with the planning of the project by simulating the production process. Firstly, we create the digital models of the product, of the moulds and of the tooling equipment; afterwards, we verify how to avoid critical situations and optimise the use of raw material and production times.

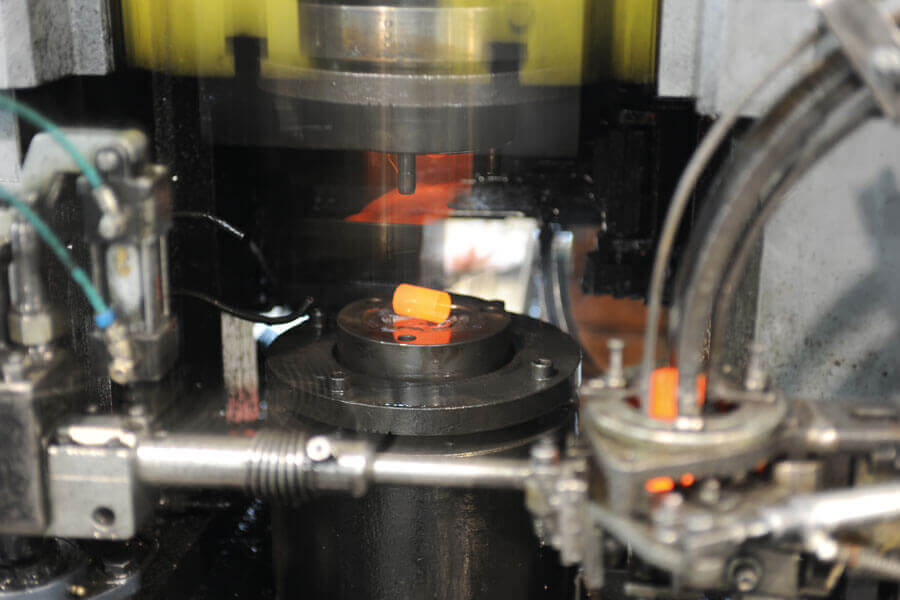

Starting from the brass bar, after the hot forging process we obtain the blank piece. At this first step of production we define how to optimise the machinery and the presses with nominal power ranging from 200 tons up to 500 tons.

We follow up the component by mechanical machining as well as by heat and surface treatments such as annealing, normalising, sandblasting, pickling, brightening, nickel-plating, chrome-plating. We take into account other treatments according to specific customer requirements.

Thanks to a wide range of transfer machines, we are able to optimise the production process and the workloads while maintaining the quality level that characterises us. The different types of tooling equipment allow us to maintain a high competitiveness on components with distinct degrees of complexity.

During each processing stage, we carry out in-line checks in order to supervise and record dimension and surface controls. We can arrange with the customer specific measurements on particular component features in order to safely guarantee the maximum reliability on the final result.

The part handling is an essential step in order to create a perfect integration with your company’s workflow. Since the beginning of the cooperation we plan the product packaging as well as the delivery terms.

Ask for a free price quotation, we will evaluate your production requirements in order to offer you a customised solution.