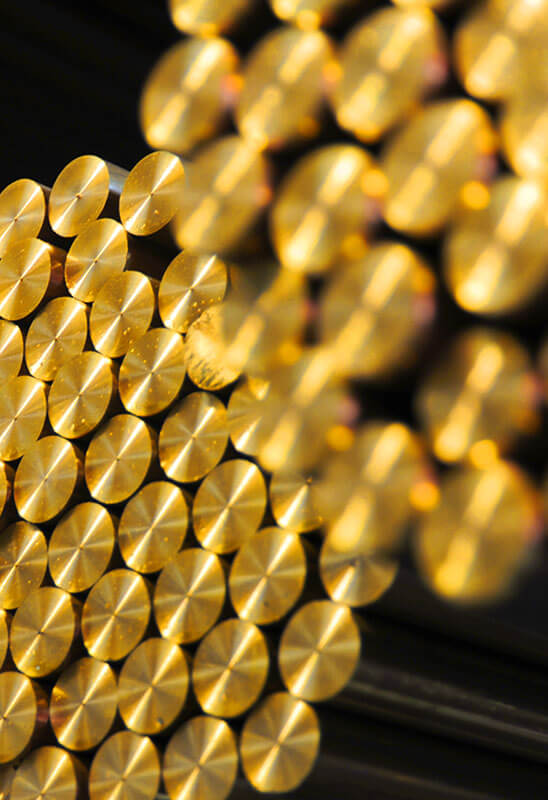

The raw material:

brassBRASS?

Among the metal alloys that can be used in industry and manufacturing, brass has excellent mechanical properties that make it the ideal material for developing complex hot forged and machined components.

Brass is an alloy consisting of copper and zinc and is mainly known for its excellent electrical and thermal conductivity as well as its resistance to corrosion.

Compared to copper, it has the advantage of having higher hardness and fusibility values.

It ensures high processability with transfer machines during both hot and cold forging.

EFFICIENCY

AND SUSTAINABILITY

Concerning the safety and environmental sustainability matter, brass has excellent antibacterial properties and can be 100% reused.

Furthermore, the brass manufacturing process is characterised by a particularly low energy cost.

DEEP TECHNICAL

KNOWLEDGE

and experience with raw material

The skills of our technical staff and the level of technological innovation and efficiency achieved by our production and design process have enabled us to specialise in the machining of a wide range of brass alloys:

CW617N

It belongs to the family of leaded brass alloys.

Lead is added to shorten or even pulverise the chips formed during machining with machine tools, reducing wear and heating of the machinery to ensure higher component quality and shorter machining times. The CW617N alloy we use is produced in accordance with Directive 2002/95/EC (RoHS) and Ministry of Health DM 174 of 6/4/2004.

CW602N

An dezincification resistant alloy with a high copper content and the presence of Arsenic which guarantees, after thermal solubilisation treatment of the beta phase, very strong resistance in contact with aggressive waters.

CW724R (ECOBRASS)

The main characteristic of this alloy is its lead content of less than 0.1%, compensated for by the presence of silicon and phosphorus, which reduce susceptibility to dezincification and stress corrosion cracking. This alloy is particularly suitable for materials in contact with water intended for human consumption (drinking water). It is a very abrasive material that at Moval we machine with state-of-the-art and high-strength machine tooling equipment.

CW625N

It is the standard dezincification resistant alloy, optimised for machining by chip removal, with low lead release values. Approved by 4MS, it is included in the “Positive List” of metallic materials that can be used in contact with drinking water.

CW626N

Created to minimise the release of lead in contact with water intended for human consumption. The presence of arsenic and aluminium reduces dezincification and lead release. It is an alloy characterised by good hot plastic deformation.

CW510L

Characterised by a lead content of less than 0.2%. The low lead content allows this brass alloy to be used in the USA, where it is NSF372 certified.

Ask for a free price quotation, we will evaluate your production requirements in order to offer you a customised solution.