16 Nov 4 benefits of hot forging

Shaping a metal component according to the required design is an extremely delicate procedure.

Precision is essential to ensure that the end part has the required structural resistance.

This is why at Moval we use the hot forging process, a material shaping technique that offers a number of very important advantages.

Hot forging: a reliable technique

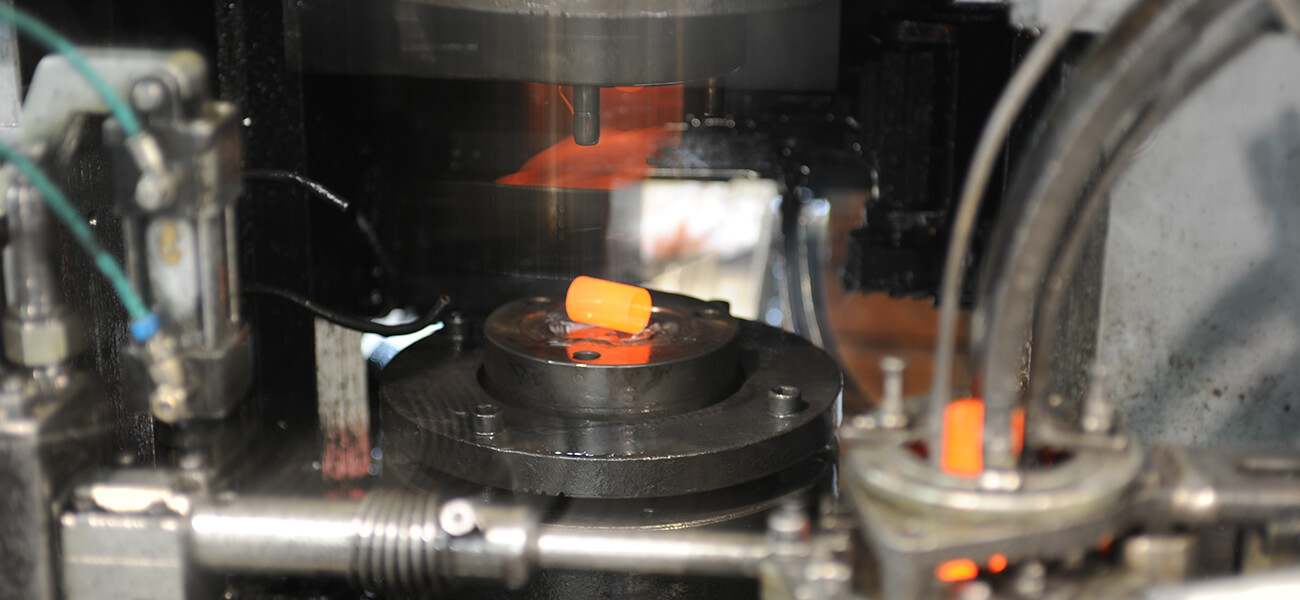

The hot forging process involves heating the material to high temperature, in this case, brass.

This makes it extremely ductile, allowing complex shapes and details to be realised.

Here are four of the main advantages of hot forging:

- Excellent mechanical resistance

Hot forging produces brass components with excellent mechanical resistance.

The high temperatures involved in the process make brass more ductile, allowing for greater strength and durability.

- Structural integrity under stress

Thanks to the hot-forging process, brass components maintain their structural integrity even in high-stress conditions.

This makes them suitable for applications where safety and durability are essential.

- Tightness

The hot forging process allows for components with a regular and micro-crack-free surface to be produced.

This means that brass components produced in this way offer a high level of tightness, which is crucial in many applications, such as the production of valves and fittings.

- Process control with state-of-the-art technologies

At Moval, we use state-of-the-art technologies to ensure the highest accuracy and quality of our components.

Advanced software and CNC equipment allow us to control every step of the hot forging process, from material supply to the production of the part.

This allows us to produce, in a short time, geometrically complex brass components with outstanding precision.

Conclusions

To sum up, hot forging is an outstanding technique for the production of customised brass components.

It offers key advantages such as higher mechanical resistance, structural integrity under stress, tightness and process control with state-of-the-art technologies.

That’s why at Moval we are the brass specialists.

With over 30 years of experience in brass machining, we offer specialised support to your engineering department and help you to realise safe and reliable customised brass components.