10 Jun Feasibility study: how we eliminate in advance possible criticalities in production

When you decide to outsource the production of a technical component, one of the most common worries is about the possible criticalities that could arise during the production stage: errors in tolerances, inaccuracies in finished parts, material waste, delays.

At Moval, we know how important it is to prevent these problems even before the first physical sample is produced. That’s why each of our projects always starts with a detailed feasibility study, which allows us to analyse and optimise the entire production process from the very beginning.

From drawing to digital simulation

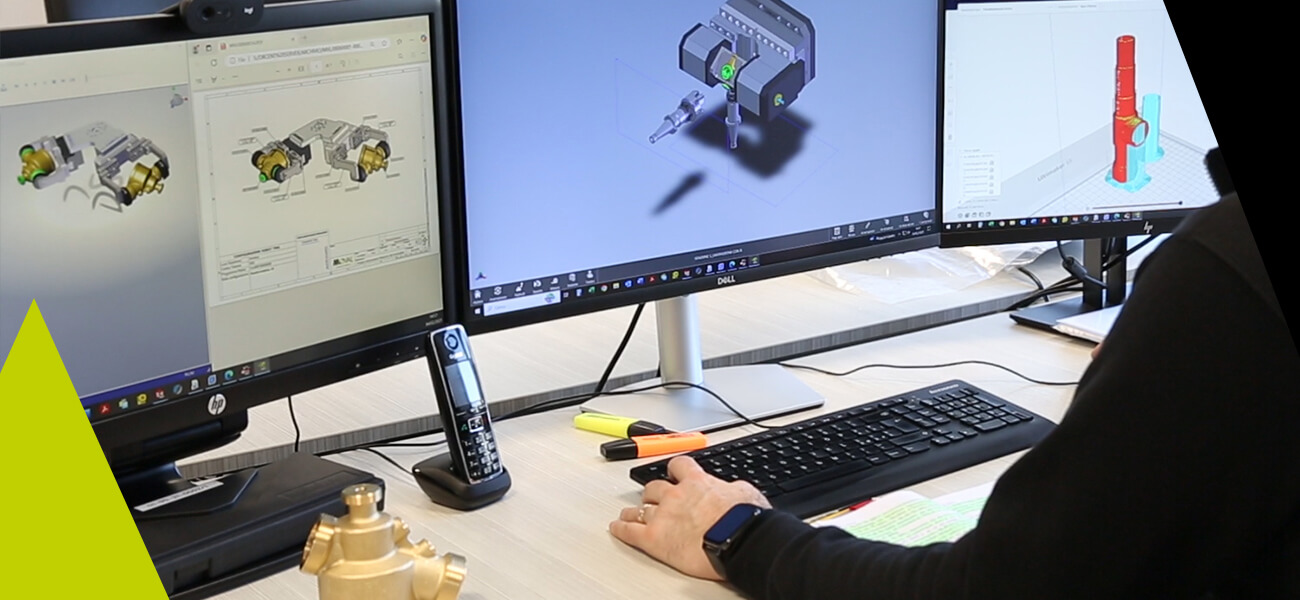

Everything starts with the technical drawings and, if available, physical samples of the component. Once this information has been gathered, we start the engineering. This means developing digital models of both the component and the moulds and tooling required for its production.

Thanks to these 3D models, we can create a virtual simulation environment in which each step of the production process is replicated: from moulding to machining, up to the delivery of the finished product.

Simulate to prevent

This phase is fundamental, because it allows us to prevent possible problems even before making the first piece. We analyse every aspect: geometries, thicknesses, tension points, machining methods, interference with equipment or tools.

The software gives us a complete and realistic overview, allowing us to optimise the project, reduce risks and, if necessary, intervene promptly with modifications or improvements.

Saving time and raw material

Along with improving the quality and precision of the component, the feasibility study also allows us to optimise the quantity of raw material and the processing time, reducing costs and making the overall project more efficient.

This is an approach that allows us to be competitive while maintaining very high quality standards, even in complex and fully customised projects.

Are you thinking about outsourcing the production of a new component?

Do you need to understand if your project is ready to be put into production or if it requires any optimisation?

Our feasibility study is designed to do exactly that: to analyse beforehand every technical aspect and offer you a more efficient, safe and sustainable production process.

Contact us to tell us about your project: we will be happy to help you turn your idea into a reliable, precise and market-ready component.